Many Quality Control (QC) departments and metrology labs face challenges with multiple software platforms tied to specific portable devices or Coordinate Measuring Machine (CMM) brands. This legacy has long caused bottlenecks—ranging from complex CMM programming to limited reporting—and, most critically, has entrenched silos among different types and brands of CMMs.

The Growing Trend of Universality on CMMs

Many Quality Control (QC) departments and metrology labs face challenges with multiple software platforms tied to specific portable devices or Coordinate Measuring Machine (CMM) brands. This legacy has long caused bottlenecks—ranging from complex CMM programming to limited reporting—and, most critically, has entrenched silos among different types and brands of CMMs.

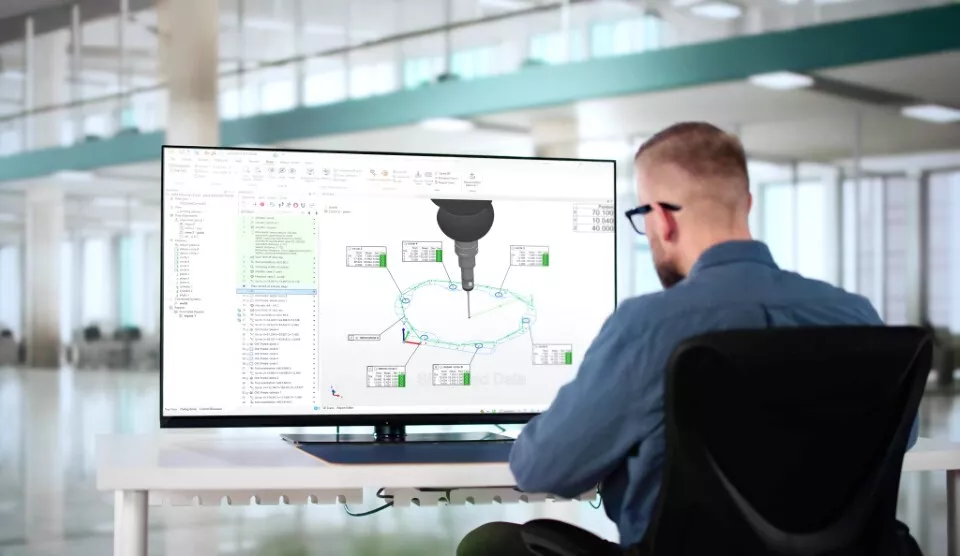

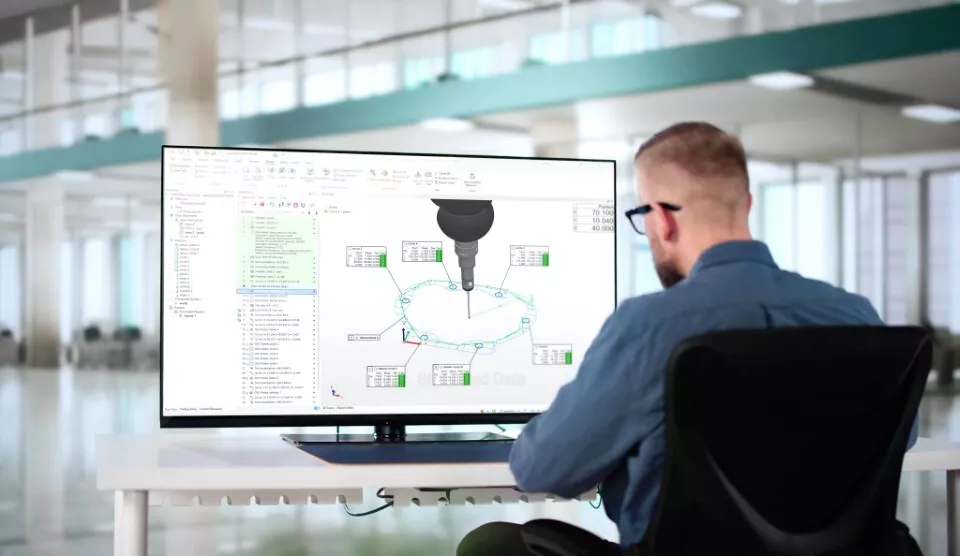

To overcome these challenges, a growing trend is emerging in the industry: universal software solutions that support CMM workflows. This shift breaks barriers by offering a modern, unified alternative that meets the demands of today’s high-speed manufacturing environment.

How a Universal CMM Software Platform Enhances Manufacturing Quality

QC leads worldwide are adopting standardized inspection processes based on three key elements:

A universal digitizing hub that is compatible with all CMMs and even other measurement devices—regardless of lab location.

Universal workflows that ensure consistent training for all operators and metrologists. Having a single interface and workflow eliminates silos, enabling every team member to work seamlessly with any CMM.

Universal projects that improve cross-utilization of resources and minimize redundant work. Inspection programs created for one CMM can be easily adapted and reused on any other CMM, eliminating duplication of effort.

In brief, this unified approach eases steep learning curves, accelerates onboarding and training, and enables seamless adaptation of inspection programs from one CMM to another. Not only does it eliminate the need for reprogramming, but it also helps companies stay flexible and agile in periods of growth or staff changes.

How Automated CMM Programming and Collision-Free Inspection Optimize Productivity

A universal CMM software platform delivers daily benefits by eradicating siloed, time-consuming manual programming routines for metrologists.

The tedious, complex process of manually programming CMMs is automated—a powerful and effortless no-code approach to generating measurement sequences. Instead of spending hours defining every path and probe angle, metrologists simply select the objects to measure. A universal software platform takes care of the rest: its intelligent sequence-editing functionality automatically determines tool orientations and generates collision-free paths that can seamlessly measure parts on any CMM.

Additional Daily Benefits for Metrologists

Below are some more valuable daily benefits for metrologists:

Universal measurement capabilities: Easily handle large CAD files, streamline non-CAD workflows, and leverage the PMI import functionality for faster setup. The software guarantees PTB-certified algorithmic calculations and offers comprehensive support for GD&T standards, ensuring accurate measurement of all required dimensions—features, surfaces, points, curves, and constructed geometry.

Actionable insights for smarter decisions: Effortlessly generate a wide range of reports—from quick ones that convey part status and highlight issues to detailed, specific ones using industry-standard templates (SPC, FAI, MSA). Reports are instantly updated with changes, and results can be shared in flexible formats as well as seamlessly across stakeholders, enabling smarter data-driven decisions.

Unify Your 3D Measurement Workflows

A universal software solution simplifies CMM inspection, unifies workflows, and empowers 3D measurement processes with the latest technological advantages—from automation and speed to full compatibility. Ready to cut CMM programming time and standardize your workflow? The solution already exists.