Accelerate Your Manufacturing Processes with Instant Access to 3D Measurement Data

10/14/25

As a QA Lead or Manufacturing Engineer, you are expected to uphold high quality standards and resolve production issues promptly. You must communicate critical information clearly, make swift decisions, and promote collaboration between multiple stakeholders.

Outdated methods of sharing 3D measurement files and inspection results, like network drives or USB sticks, slow you down.

They can also result in duplicate files, siloed data, and tedious searches for the right information. It’s like digging through an old file cabinet—an overwhelming sea of data with no efficient way to navigate it.

Your 3D Data, Centralized and Actionable

With centralized access, managing 3D measurement data shifts from being a burden to an asset for manufacturing process improvement. Instant access to your 3D data enables you to:

Decide faster: Access inspection results in real time for root cause analysis and trend reporting.

Collaborate seamlessly: Ensure everyone works from a single source of truth.

Streamline workflows: Avoid wasting time searching for files, transferring data, or fixing version errors.

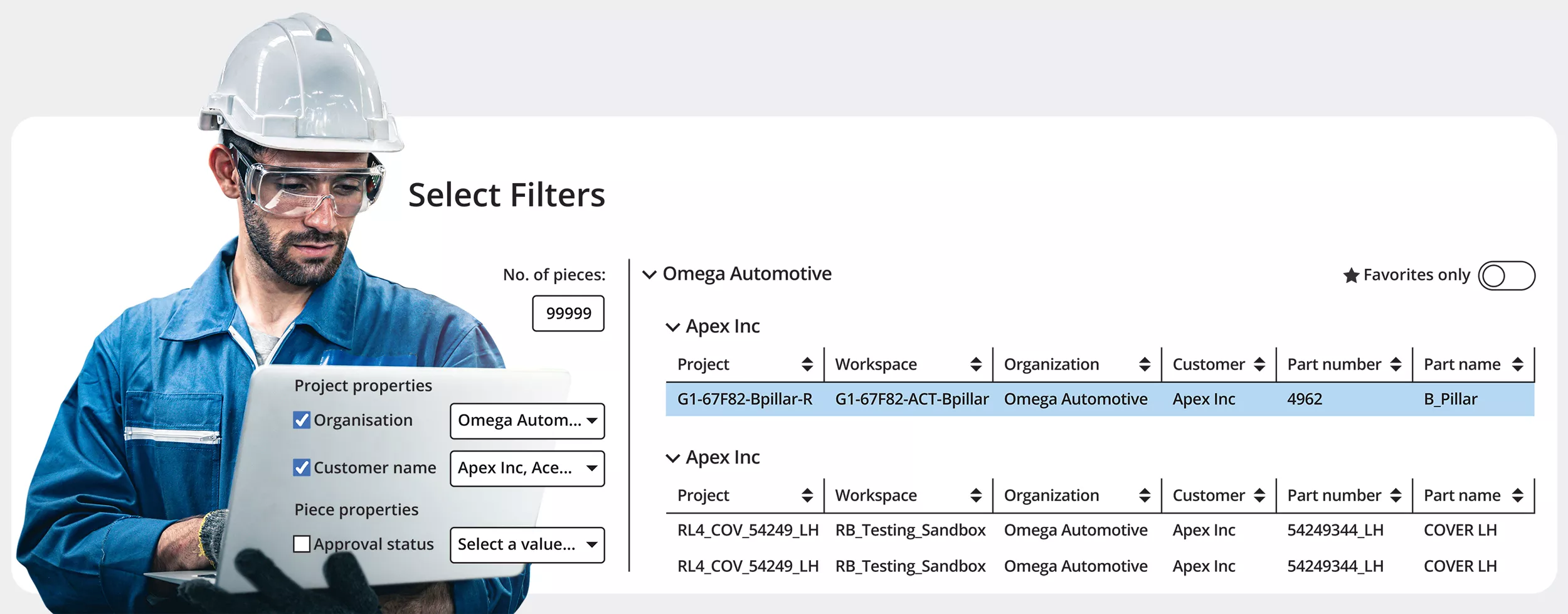

A modern data management system consolidates all your 3D measurement files into a secure, searchable hub. Instead of wasting time hunting through files, you can leverage intuitive indexing, search, and filtering tools to seamlessly find and access data based on part number, serial number, or production line.

Seamless Collaboration in Real Time, Anywhere

Manufacturing is a team effort. Your project collaborators may work remotely or be spread across multiple sites. Old habits like emailing large attachments add delay and friction to the process, but a centralized platform removes these barriers.

With instant hyperlink-based access to 3D data on any device, your QA and engineering teams can:

Accelerate reporting by granting immediate access to all stakeholders

Review inspection results—anytime, anywhere

Troubleshoot with colleagues across different locations using synchronized data

Challenges become opportunities for collaboration, data-driven decisions, and continuous improvement.

Turn Your 3D Data Into Actionable Insights

Your expertise drives manufacturing quality, while a robust data management infrastructure ensures seamless access. Together, they unlock the full potential of your 3D measurement data.

The result? More time for problem-solving, greater confidence in every decision, and stronger synergy across your organization.

Your expertise is too valuable to be bottlenecked by time-consuming data digging.

Want faster workflows, smoother collaboration, and higher product quality—powered by up-to-date, unified data? Request a PolyWorks|DataLoop™ demo to assess how this solution can transform your manufacturing processes.

About InnovMetric

InnovMetric is an independent software development company that empowers manufacturers of every size to digitally transform their 3D measurement processes. InnovMetric has revolutionized 3D metrology with the introduction of point-cloud-based dimensional inspection in 2000 and the concept of a universal 3D metrology software platform in 2006.

Today, with over 23,000 customers in 100 countries, and the world’s largest industrial manufacturers having adopted its PolyWorks® solutions as their standard 3D metrology software platform, InnovMetric is focusing on creating next-generation digital data and process management technologies.

Watch this video to discover the story behind InnovMetric’s mission, people, and passion for innovation.